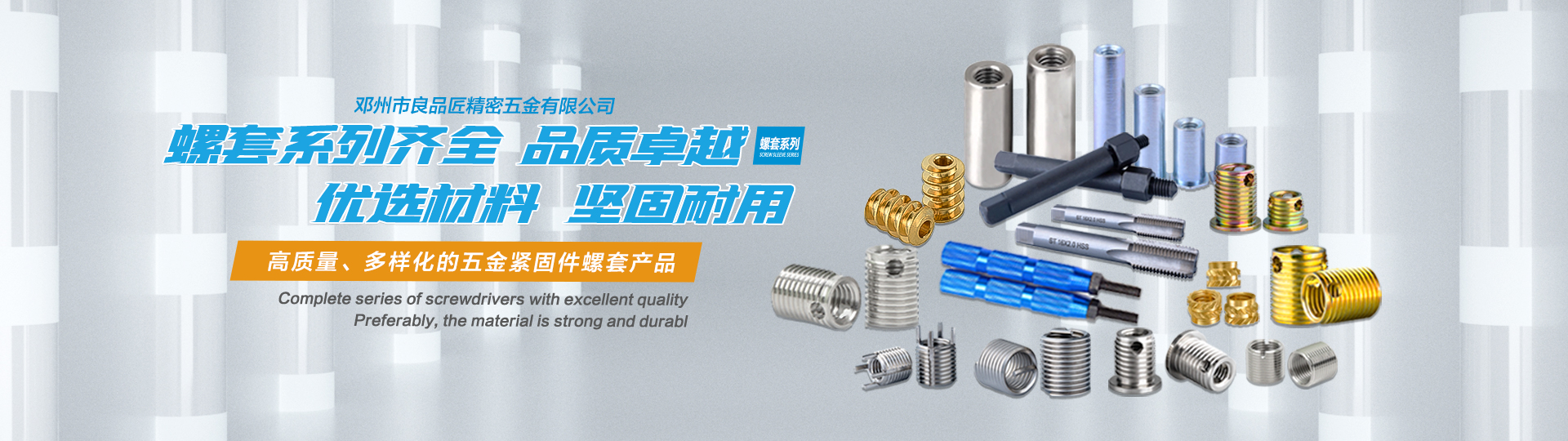

Liangpinjiang Precision Hardware - Professional Fastener Factory - High-Quality Nuts, Bolts, Threadi

2008

Professional Fastener Factory

Dengzhou Liangpinjiang Precision Hardware Co.Ltd., a dedicated manufacturer specializing in precision hardware. We strive to provide our customers with high-quality fastener products. With our professional fastener factory, we produce a range of precision hardware fasteners, including high-grade nuts, threading dies, and threaded sleeves, to cater to various industry needs. As a direct manufacturer of top-notch nuts and threading dies, we ensure strict quality checks on every product, guaranteeing our customers an exceptional product experience. Choosing Liangpinjiang means choosing professionalism, reliability, and quality. We look forward to collaborating with you to create a bright future.

- By exercising strict oversight over the quality of raw materials

- Refusing to produce faulty goods

- Preventing their outflow

- Rejecting any imperfections

- We ensure that your choice is safer and more secure

Products We Offer

302 Self-Tapping Inserts

Keyed Threaded Insert

Heavy-duty pin insert thread

Contact Us 18025841237

If you have any questions or require assistance, please feel free to contact us, and we will promptly address your concerns and provide the necessary support.Guaranteed Quality

With years of expertise in the high-quality nut, screw thread insert, and tap fastener industry, we have grown into a leading super factory of fastener nuts and taps, leveraging our remarkable technical strength and unwavering spirit of innovation. Equipped with advanced production machinery and technology, we ensure the stability and reliability of our product quality. Every product strictly adheres to GB, ANSI, ASME, IFI, BS, GOST, ISO, and other regulations. In the selection of raw materials, we consistently adhere to high standards and strictly control the quality of raw materials. Furthermore, we boast a professional after-sales team that provides prompt and efficient service support to our customers. Choosing us means choosing a dual guarantee of quality and service.

1000+

Marketed Company

200+

Team Members

100%

Satisfaction Rate

100+

Products

Latest Projects

Answers to frequently asked questions

What They’re Say About Us?

During our collaboration, we have demonstrated exceptional professionalism and dedication, earning widespread praise from our clients. Our solutions and service quality have received high commendations, tailored to meet the needs of our clients and providing practical support. Additionally, our team's seamless collaboration and prompt response capabilities have been highly appreciated, as we swiftly and actively address various challenges. We eagerly look forward to making further outstanding contributions to our clients and sincerely hope that more clients will choose to partner with us, jointly creating a brighter future.